Micro Fibre Pollution

Micro fibres have been found in water and food sources across the globe and are a concern for human and planetary health. We tested different variables affecting fibre shedding, such as fibre type or yarn twist to provide recommendations for industry.

Micro fibres are short pieces of textile fibre that are released from the yarn, fabric, or garment during production or when users wash their garments at home. Micro fibres have been found in water and food sources across the globe and are a concern for the environment even if their exact effect on human and planetary health is yet unknown.

Even biobased yarns and textiles shed micro fibres which may not degrade in water, it is therefore important to understand what measures mitigate fibre shedding across the textile supply chain.

This report lays out the results of tests with different variables affecting fibre shedding such as fibre type or yarn twist, to identify recommendations for industry.

What is micro fibre pollution?

Fibre fragments are short pieces of fibre, typically less than 5 mm long, released from the main textile structure. These fragments, synthetic or of natural origin, can be released during, and be influenced by, all phases of the product life cycle. These small fragments pollute the environment and are regarded as a risk, although more research is needed to fully understand their impact.

Why do we need to reduce fibre pollution?

While little is known about the effects of fibre fragmentation on the environment and more research is needed in this area, fibre fragmentation is a known source of pollution which must be mitigated.

Micro fibres are persistent in the environment and have been found in various human food sources such as seafood, salt, beer, and drinking water. Currently there is a lack of understanding of this issue, partly because multiple characteristics can affect the fibre shedding tendencies of a fibre, yarn, textile or garment. It is important to better understand what processes and treatments affect the levels of shedding so that fibre pollution can be mitigated across the supply chain

How can we reduce fibre pollution?

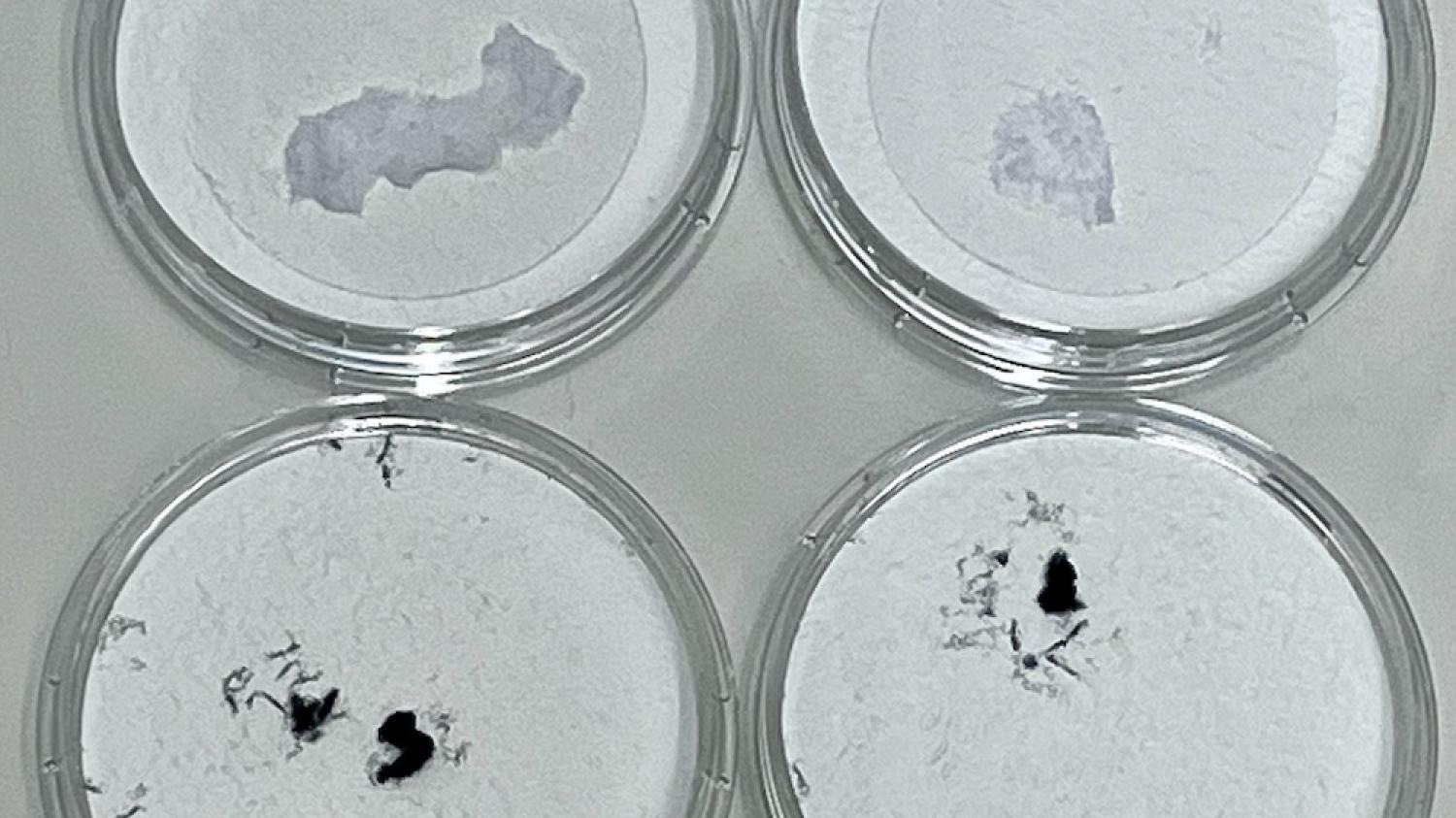

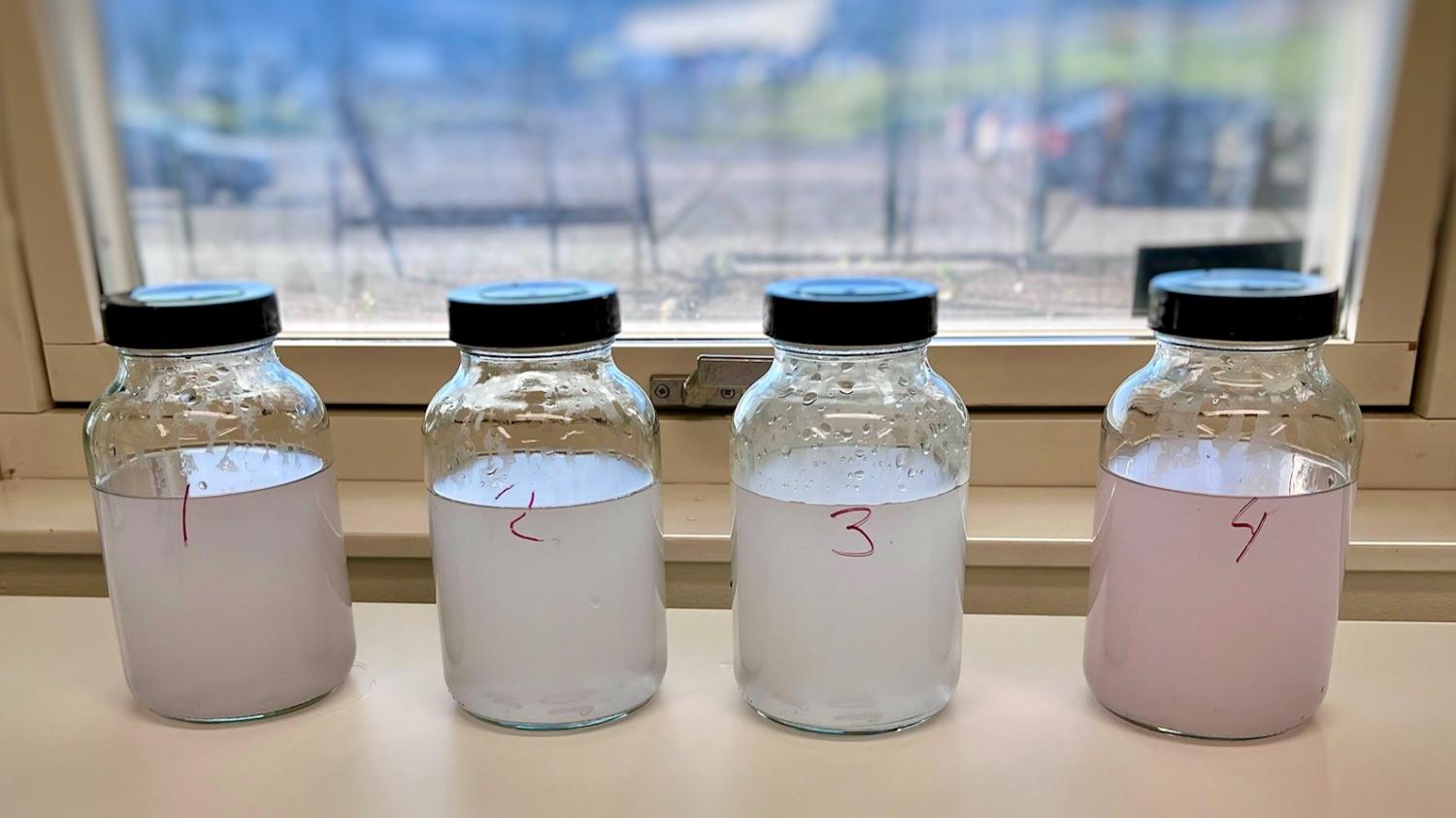

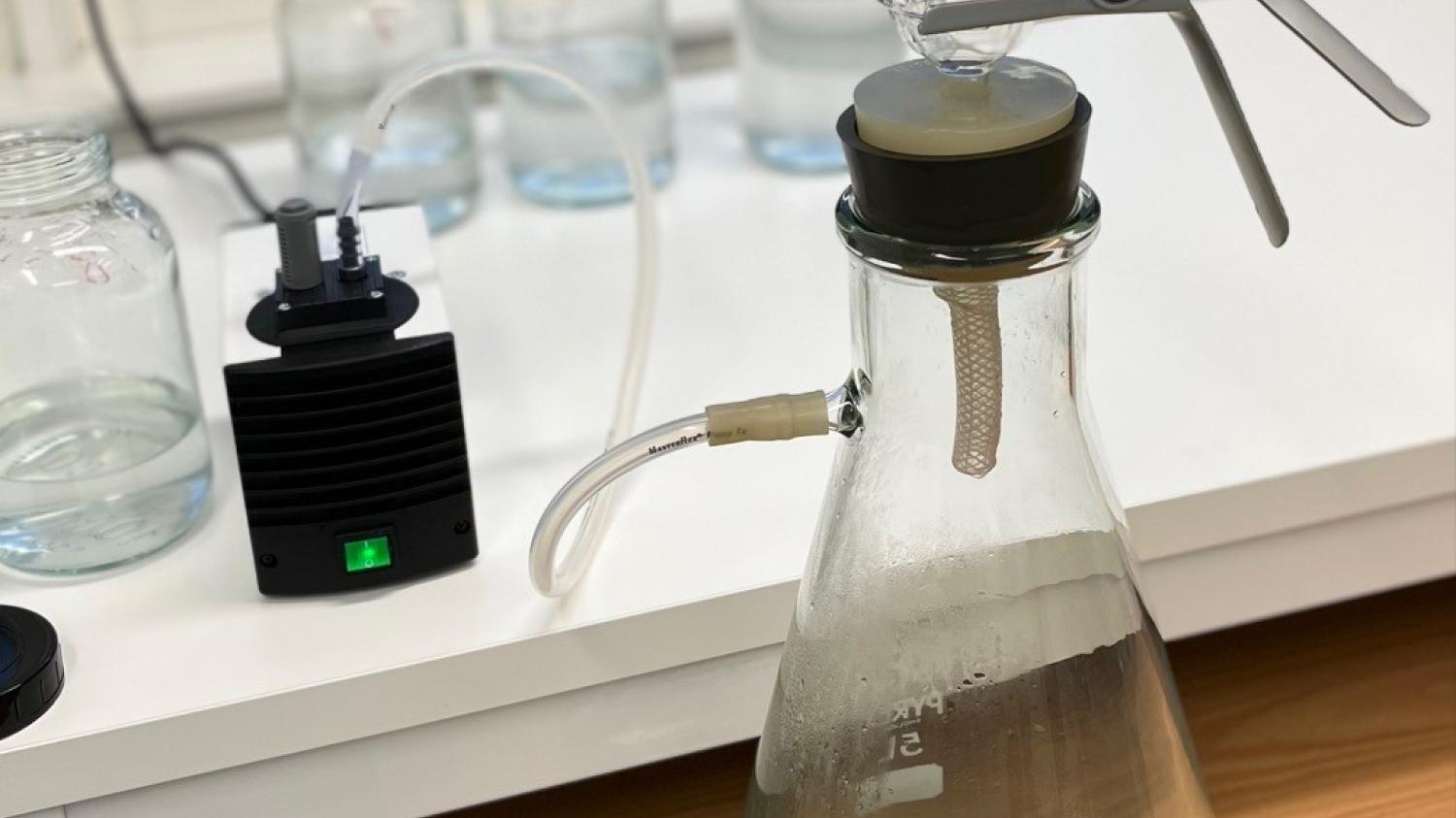

In HEREWEAR we tested a selected range of textiles to provide recommendations to the textiles industry. Fibre shedding may vary depending on a range of factors such as the construction of the fibres and textiles under investigation. To learn more about how to test the fibre shedding tendencies of textiles, there is an ISO standard which lays out the testing steps.

HEREWEAR researchers have identified the stages in the manufacturing process where actions can be taken to reduce fibre shedding. All production stages from fibre to garment manufacturing, including finishing processes must be taken into account during testing. Measures such as choosing filament fibres rather than staple fibres, or applying special finishes can be taken by industry stakeholders to mitigate shedding.

Good to know!

- Micro fibre shedding is influenced by decisions made at each stage of the textile supply chain, so it is important to get all stakeholders on board.

- The following standard is available for purchasing: EN-ISO 4484-1-2023 “Textiles and textile products – Microplastics from textile sources - Part1: Determination of material loss from fabrics during washing.

- While some biobased fibres can be biodegradable in some conditions, it is unlikely that they will degrade in water or marine environments, especially if dyes and finishes have been applied to them. It is therefore essential to limit shedding even for biobased materials.

So you want to reduce micro fibre shedding?

There are recommendations you can follow at each stage of the manufacturing process that will reduce the risk of shedding.

- Stage 1: Fibre Manufacturing. It has been found that the use of filament fibres over staple fibres reduces shedding.

- Stage 2: Yarn Manufacturing. A higher fibre twist can decrease shedding. This is applicable mainly to staple fibres. When using filament fibres, texturizing effects will increase shedding but will still be better than staple fibre yarns.

- Stage 3: Textile manufacturing: Tighter constructions in woven and knitted fabrics reduce fibre shedding

- Stage 4: Textile Finishes. Finishes can be applied to reduce fibre shedding, and processes such as brushing can be controlled to mitigate shedding.

- Stage 5: Garment Manufacturing. Alternative cutting methods such as laser or ultrasound can be used to reduce fraying and fibre shedding.

Any mechanical or chemical processes that damage the fibre may increase the chance of fibre shedding.

What to do next

Suggested reading & viewing

Academic articles:

- Microfibers in oceanic surface waters: A global characterization - PubMed (nih.gov) Giuseppe, S., et al., (2020) “Microfibers in oceanic surface waters A global characterization” Science advances.6 : eaay8493

- Estimation of the mass of microplastics ingested - A pivotal first step towards human health risk assessment - PubMed (nih.gov) Senathirajah, K., et al, (2021) “Estimation of the mass of microplastics ingested – A pivotal first step towards human health risk assessment” Journal of Hazardous Materials 404, 124004

- Effect of Textile Parameters on Microfiber Shedding Properties of Textiles. Raja Balasaraswathi, S., Rathinamoorthy, R. (2021). In: Muthu, S.S. (eds) Microplastic Pollution. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry. Springer, Singapore. https://doi.org/10.1007/978-981-16-0297-9_1 https://link.springer.com/chapter/10.1007/978-981-16-0297-9_1

Other projects:

- RISE MinShed project: https://www.ri.se/sites/default/files/2022-11/MinShed%20_report_final_2022-03-30_0.pdf

Micro Fibre Testing:

- The Micro Fibre Consortium Test Method: https://static1.squarespace.com/static/5aaba1998f513028aeec604c/t/611bd9da5a5b2e4c66623c21/1629215194569/TMC+Test+Method_FAQs.pdf

Organisations taking action on fibre pollution:

- The Micro Fibre Consortium: https://www.microfibreconsortium.com/

- European Textile Confederation (EURATEX): https://euratex.eu/

- The ZDHC Roadmap to Zero Programme: The Microfibre Consortium and ZDHC Foundation Unite to Combat Microfibre Release (roadmaptozero.com )

- UNEP: Marine Plastic Debris and Microplastics- Global Lessons and Research to Inspire Action and Guide Policy Change: https://www.unep.org/resources/publication/marine-plastic-debris-and-microplastics-global-lessons-and-research-inspire

- Forum for the Future: Tackling micro fibres at source: https://www.forumforthefuture.org/tackling-microfibres-at-source

- Foundation, P.S, Microfiber release from clothes after washing: Hard facts, figures and promising solutions”: https://www.mdpi.com/2079-6439/11/12/105

- Textile Mission, Reducing Textile Microplastics: https://textilemission.bsi-sport.de/fileadmin/assets/Abschlussdokument-2021/TextileMission_Report_English_Online_2.pdf