Pushing Biopolyester to the limit: Mitwill's story

Mitwill took a challenge approach to the garment design; they wanted to test the material capabilities by applying them to their existing hard-working corporate polo shirts, which are usually made from fossil-based polyester.

Novel materials are continuously being developed from scientific discoveries, and the development of new technologies in response to changing needs of society and the environment. In HEREWEAR we wanted to go a step further and test our novel materials for commercial products with industrial partners to demonstrate their suitability and viability for designing and manufacturing garments.

In this section you can find out about the EthEco Collection, designed and produced by corporate-wear brand Mitwill in collaboration with the HEREWEAR partners.

What is the EthEco Collection?

Mitwill took a challenge approach to the garment design; they wanted to test the material capabilities by applying them to their existing hard-working corporate polo shirts, which are usually made from fossil-based polyester. Mitwill decided to see if the scratchy and crunchy biopolyester multifilaments could make a comfortable textile for all-day wear in a work environment.

The EthEco Collection represents three different design approaches:

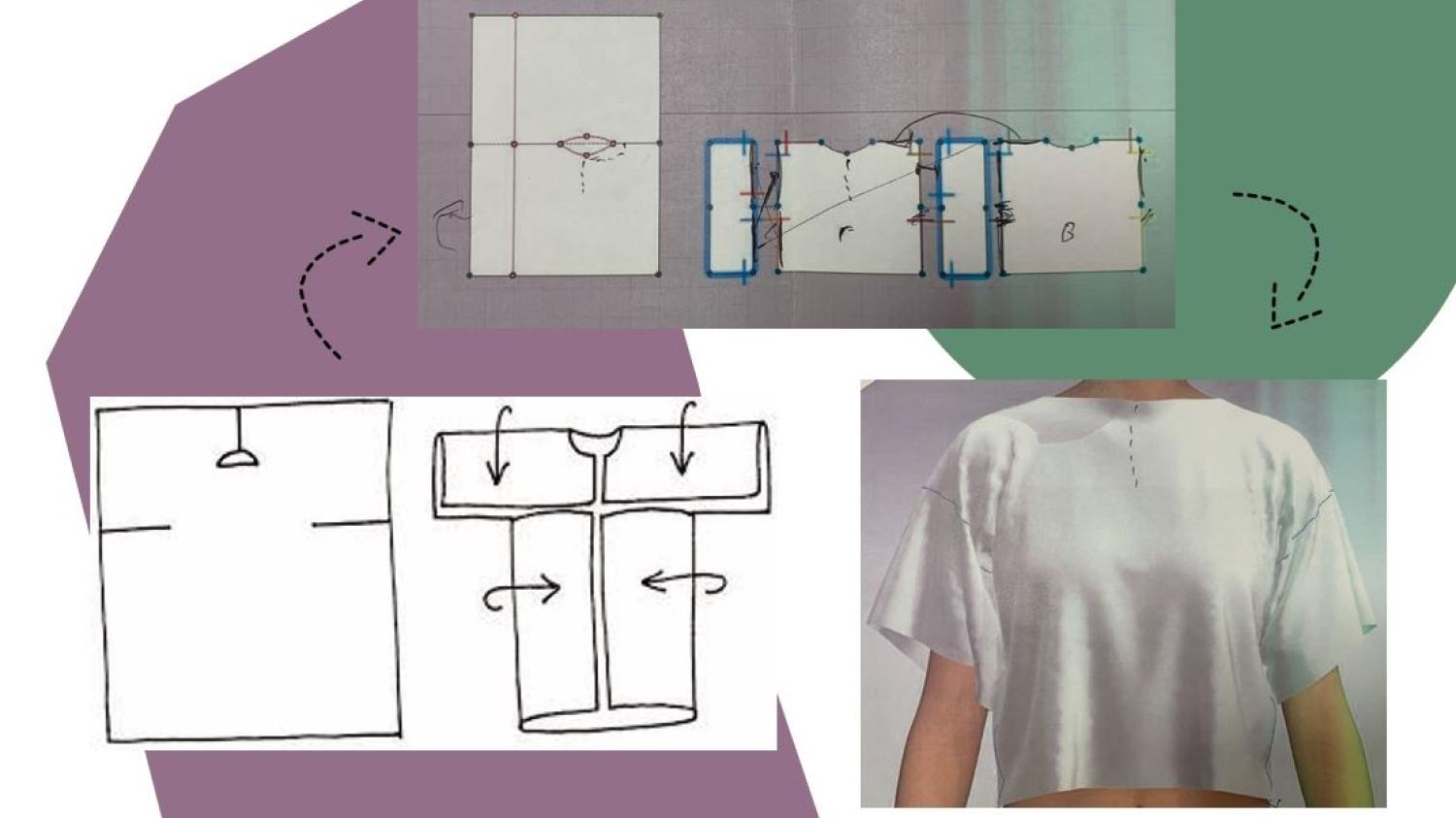

- 0 Shirt - a mono material, boxy fit slit T-Shirt, made using a zero-waste pattern

- -1 Shirt - a mono material, fitted raglan Polo Shirt, with slight cutting waste

- 3D Shirt – a mono material, longsleeve t-shirt, made by a whole garment knitting technology called knit&wear® by Stoll , also known as 3D knitting (ideally)

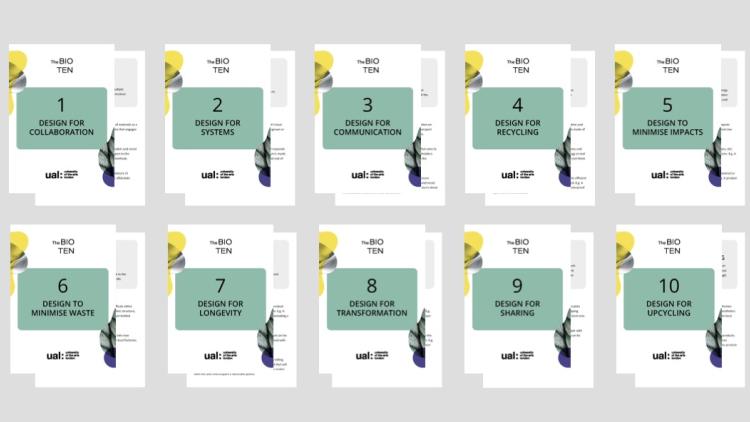

The EthEco collection is designed with the following features for Circular, Bio-based and Local textile ecosystems:

- 3D garment simulation to avoid the first 2-3 prototypes and waste

- Product Passport through circular.ID service

- Digital and networked manufacturing structures

- Max. 5% waste for final product targeted

- Unisex to enable multiple uses and support non-binary style

- Innovative whole garment knitting technology to reduce waste and for longevity through improved fit

How did we design and produce the Day Shirt?

There were five main steps to the garment development process:

- Creative Exploration - using design guidelines and tools

- Early Prototyping - to explore materials and production steps

- Materials Sampling – to explore the possibilities of the materials for the design

- Circularity Checks and Local Modelling – to ensure the design meets the HEREWEAR criteria

- Creation of Tech Packs incl. digital designs - to test the prototypes and develop for production

The main challenge was to create a comfortable and skin-friendly textile from biopolyester which tends to be ‘crunchy’ and rough to touch, with poor dimensional stability.

After many material trials and collaboration between partners, several suitable knitted biopolyester samples were developed for the EthEco Collection, with improved comfort, cover and dimensional stability in undyed and charcoal colours.

More detail on how this was achieved can be found in the Bio-based Textiles and Biopolyester sections of the HUB.

What to do next

Suggested reading & viewing

Find out more about Mitwill design, printing and microfactory: https://mitwilltextiles.com/