Biopolyester Fibres

Biopolyester is a material made from renewable materials that can be used to make fibres and textiles with properties similar to conventional fossil-based polyester.

Around 55% of clothing is made using conventional fossil-based polyester because it is strong, durable and inexpensive. However, the production of conventional polyester relies on the continued extraction of fossil-based oil, and so its production and global transportation have significant environmental and social impacts.

In this section you can find out about one of the most promising biopolyesters for textiles, Polylactic Acid (PLA), what it is, how it is made into fibres and what we discovered about how to process PLA in place of conventional polyester.

Why PLA?

PLA is commercially available in large quantities and at lower cost when compared to other bio-based polymers.

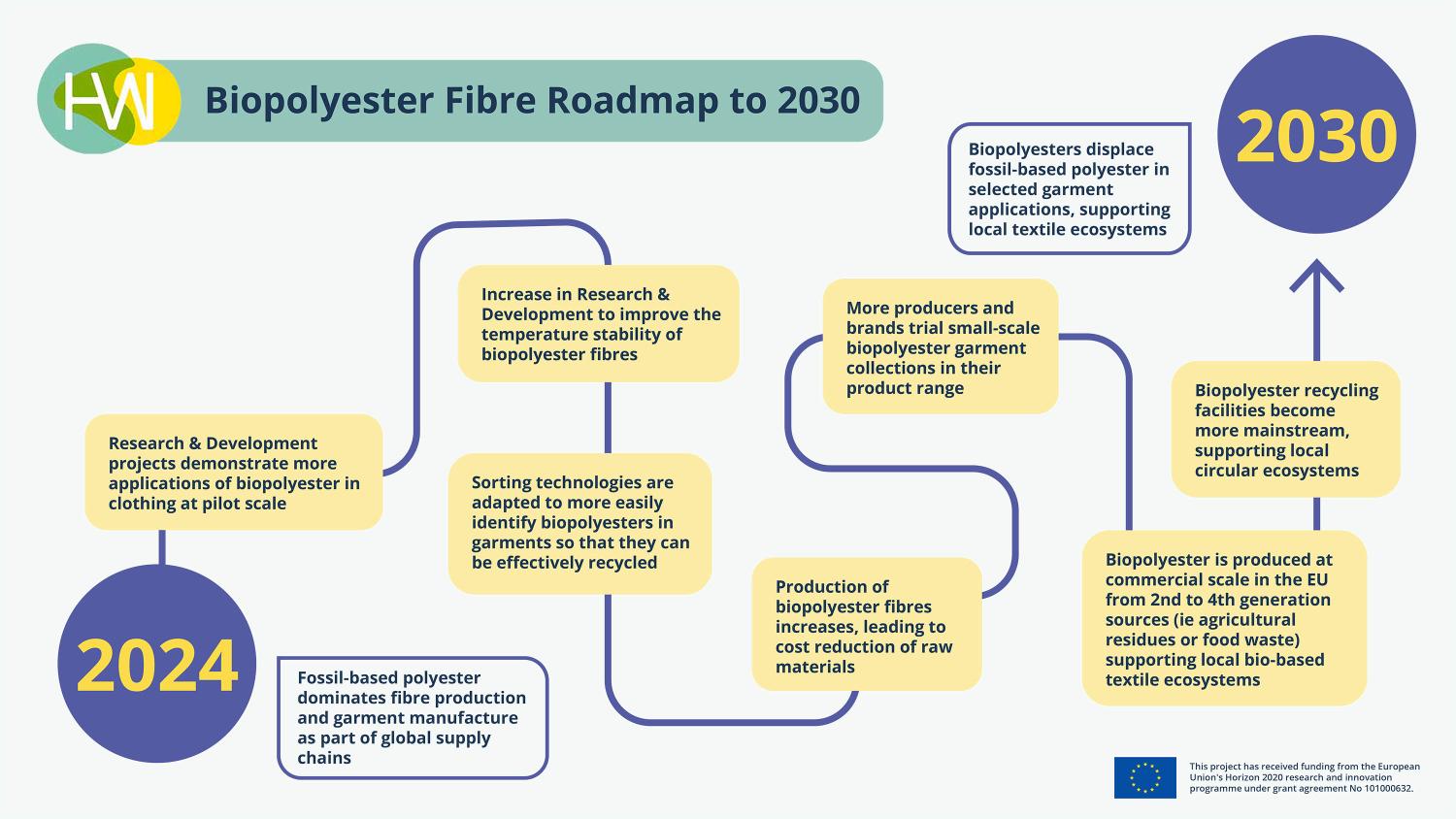

Recent technological developments are helping the textile industry to transition away from conventional fossil-based polyester, including improved polyester recycling technologies and infrastructure.

The development of biopolyesters for textiles and clothing offers another opportunity to support this transition away from fossil-based oil. Biopolyesters can also help to localise material production when made from renewable, locally-produced raw materials.

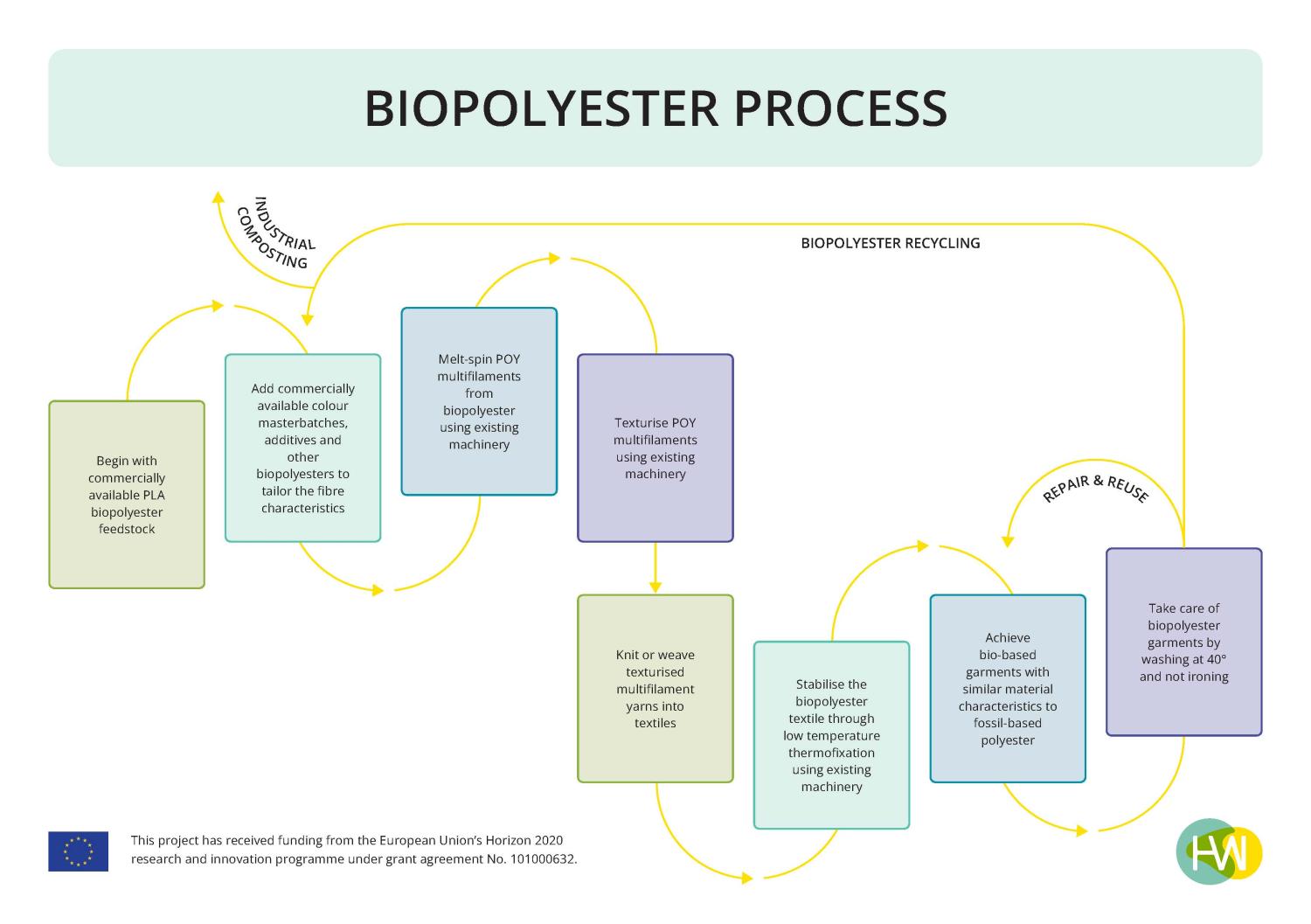

How is PLA made into biopolyester fibres?

PLA is made from plant starch such as corn and sugarcane. Work is ongoing to produce PLA out of secondary, third or even fourth feedstocks such as agricultural residues so that its production doesn’t take resources away from growing food.

Melt-spinning is used to make fibres from PLA because it doesn’t use solvents and is a simple economical process. The PLA chips are melted and forced through tiny holes to produce continuous filaments that are then drawn out onto rollers.

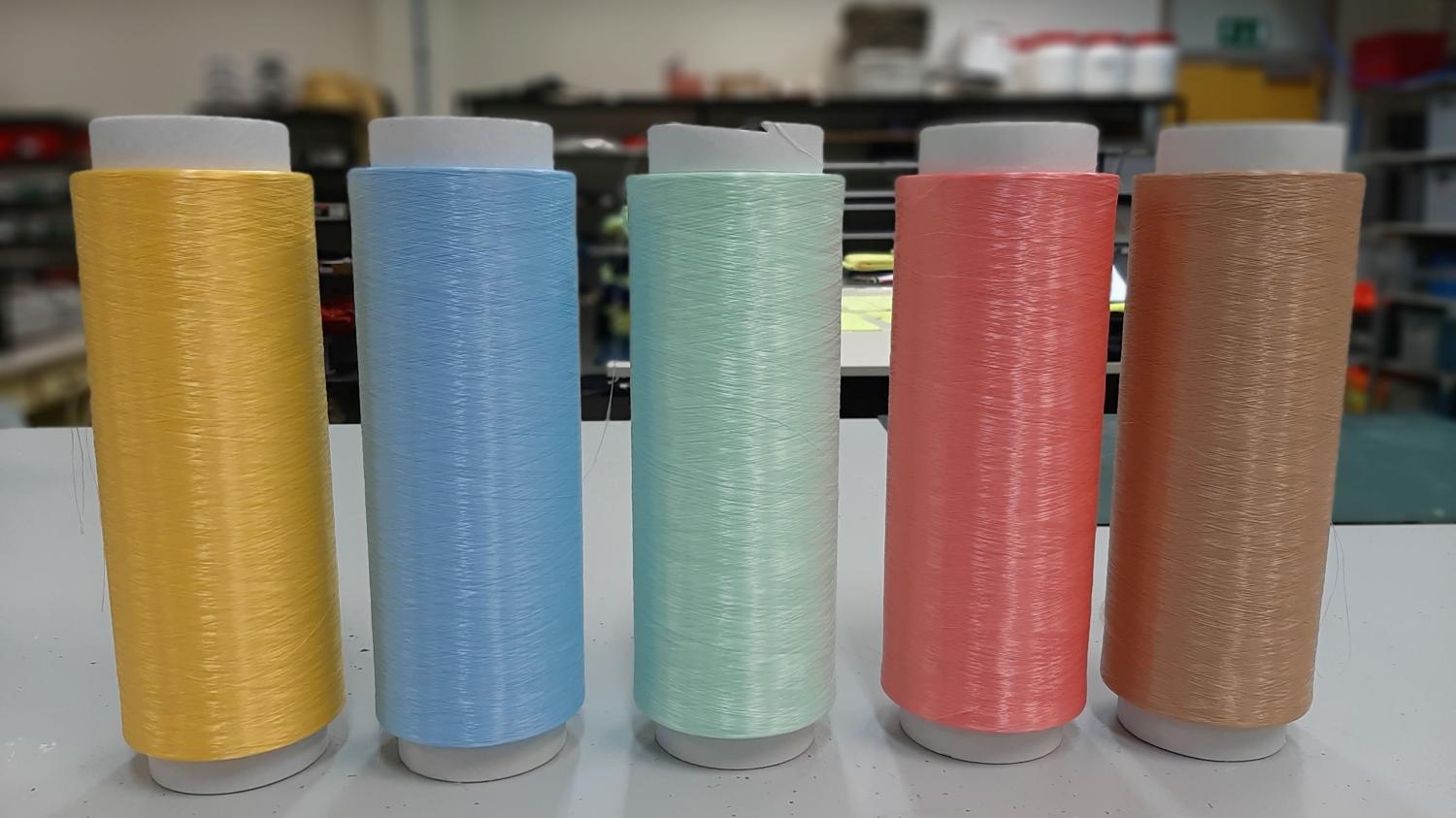

To make PLA fibres soft enough for clothing, biopolymers with different properties can be added and the filaments can be texturised providing volume and comfort. Colour can be added to the polymer which may reduce additional dyeing steps later in the textile production.

Good to know!

- PLA fibres have controlled crimp, smooth surface and low moisture regain, fairly good mechanical properties, dyeability, high resilience, good flame-retardant properties, good UV stability and low odour retention.

- PLA has some drawbacks that may need to be overcome. PLA fibres have a ‘crunchy’ and rough touch when woven into textiles. This can be tackled by blending PLA with other bio-polymers, such as Polybutylene Succinate (PBS), polyhydroxyalkanoates (PHAs), or poly-trimethylene terephthalate (PTT).

- Man-made synthetic yarns as such are generally very smooth, complicating their further processing and impacting their feel. Texturing restructures the smooth surface of the filament making it more voluminous with improved softness, bulk and covering capacity.

- PLA textiles should not be ironed because they have a relatively low melt temperature, but they are fairly resistant to creasing.

- PLA can only be considered ‘biodegradable’ in industrial compost facilities, and to maximise the invested resource in the materials, specialist PLA recycling is the preferred end of life option.

So you want to spin biopolyester fibres?

Here are some useful highlights from our research:

- Existing melt-spinning equipment is suitable for spinning PLA fibres

- The melting temperature of PLA is lower compared to standard fossil-based polyester (175 °C for PLA compared to 265 °C for polyester)

- A lower thermofixation temperature is needed

- PLA fibres are strong enough for general textiles but not for applications which require high-tenacity yarns (25% lower tenacity than conventional polyester)

- Colour masterbatches and carbodiimide based hydrolysis stabiliser (commercially available) can be added without affecting processibility or mechanical properties.

- Up to 20% of other biopolyesters may be added for softness without affecting processibility or mechanical properties.

What to do next

Suggested reading & viewing

- PLA producers:

Total Energies Corbion

NatureWorks

Futerro - PLA fibre/yarn suppliers:

PLA filament yarns innovative and sustainable - Trevira

Polylactic Acid PLA - Grades (swicofil.com)

Noosa - PLA clothing producers:

NILMORE - PLA recyclers:

FUTERRO

Noosa

Total Energies Corbion - Centexbel:

R&D projects

Pilot platforms for testing - Standardisation:

Bio-based products (CEN/TC 411): with working groups on Terminology; Bio-based content; Sustainability criteria, life cycle analysis and related issues; Certification and declaration tools