Man-Made Cellulosic (MMC) fibres

HighPerCell® is a MMC fibre spinning technology which can produce continuous filaments from various sources of cellulose, and has been used to produce the first 100% continuous MMC filament from wheat straw.

For many years cotton has been the most common plant-based fibre for clothing. In more recent years Man-Made Cellulosic (MMC) fibres, which are also made from plant cellulose, have grown in popularity and are an important new fibre to help meet demand for cellulose fibres.

HighPerCell® is a novel MMC fibre spinning technology which can produce continuous filaments from various sources of cellulose using a direct dissolution process based on ionic liquids as solvent. In the HEREWEAR project, HighPerCell® has been used to produce the first 100% continuous MMC filament from wheat straw.

In this section you can find out how we spun golden fibres from straw, we discuss the benefits of the HighPerCell® process and how the fibres behave compared to conventional MMC fibres.

What are ManMade Cellulosic fibres (MMCs)?

Whereas cotton is mechanically spun into yarns for textiles, MMCs are chemically transformed into fibres. The most common method for producing MMC fibres is the Viscose process.

MMCs are usually made from the cellulose found in wood, but there are many plants containing cellulose such as bast fibres, nettles and miscanthus that could be used to make fine fibres suitable for clothing.

Why are new MMC technologies being developed?

Cotton production typically involves the use of large quantities of water, energy and pesticides. Cotton production is also declining as land availability, population growth and climate changes limit its growth. This has led to increased production of MMC fibres using the viscose process to transform wood cellulose into cotton-like yarns.

However, the viscose process creates chemical by-products, such as hydrogen sulfide (H2S) and carbon disulfide (CS2) that can be harmful to people and the environment.

Alternative fibres made from renewable resources that don’t compete with food production (like cotton) and do not use hazardous chemicals (like viscose), are needed.

How does the HighPerCell® technology work?

HighPerCell® was developed as an alternative MMC process to viscose, that uses safer chemicals in a closed system to reduce the harmful effects to people and the environment. The HighPerCell® process can accept alternative sources of cellulose, including agricultural residues such as wheat straw, and creates continuous filaments that are not prone to breaking and fibre shedding.

Wheat straw pulp, prepared by the biorefinery, is dissolved in Ionic Liquid to form a ‘spinning dope’, like a cellulose ‘soup’. The dope is then forced through tiny holes to form continuous filaments that are drawn through a water bath and onto hot drying rollers.

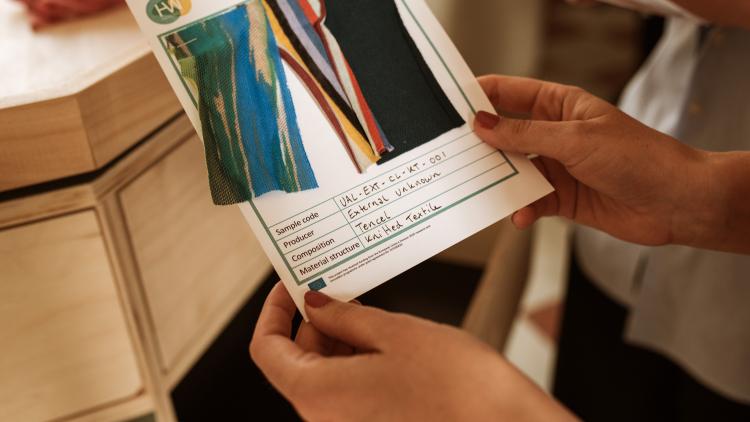

Multi-filaments can then be combined to form yarns for knitting and weaving textiles to make clothing.

Good to know!

- The unbleached filaments retain the golden shimmer of the wheat straw.

- HighPerCell® filaments are strong when wet, which means they don’t break easily when washed and worn.

- Wheat straw filaments spun using HighPerCell® are as strong as viscose fibres

- Solely recycled ionic liquid was used for spinning filaments within HEREWEAR.

- HighPerCell® filaments made from wood and wheat straw were tested by ASTM D6691 for marine biodegradability. All samples pass a relative degradation rate of 90% after 28 days.

Here are some highlights from our research:

- HighPerCell® spinning process allows the production of endless multifilament yarns over a broad range of filament properties suitable for textile and technical applications.

- Using the HighPerCell® technology, 100% recycling of all components (biopolymer cellulose, ionic liquid and water) is possible.

- Upgraded wheat straw pulp is comparable to hardwood pulp in terms of cellulose and ash content.

- By varying the HighPerCell® processing conditions, filaments with low and high wet fibrillation tendency can be produced without the need of chemicals or time-consuming post-treatments (as is the case for other MMCs).

- The HighPerCell® process is very tolerant and flexible in its raw material acceptance, especially compared to industrial processes

- HighPerCell® has been demonstrated as a circular technology, enabling fibre to fibre recycling. Both pre- and post consumer textile waste can be processed to new fibre

What to do next

Suggested reading & viewing

HighPerCell® Licence Holder

- Technikum Laubholz GmbH (HPC licence holder) Cellulose Innovation Award

https://cellulose-fibres.eu/award-application/

Projects

- Iroony - RBX Creations https://www.iroony.net/

- New Cotton https://newcottonproject.eu/

Alternative MMC fibre technologies

- Spinnova https://spinnova.com/

- Infinited fiber https://infinitedfiber.com/

- HeiQ AeoniQ https://www.heiq-aeoniq.com/

- Tree to Textile https://treetotextile.com/

- Metsa Group https://www.metsagroup.com/

- Ioncel Oy https://ioncell.fi/