Turning Straw into Gold: Vretena's story

For the Flexi-Dress Vretena took a Material-First Approach. The focus is on the emotional connection to the HighPerCell® material, where the golden hue comes from the unbleached wheat straw fibres, to achieve a local and circular product.

Novel materials are continuously being developed following the development of new technologies and in response to changing needs of society and the environment. In HEREWEAR we wanted to go a step further and test our novel materials with industrial partners to demonstrate their suitability and viability for designing and manufacturing garments.

In this section you can find out about the Flexi-Dress, designed and produced by micro fashion brand Vretena in collaboration with the HEREWEAR partners.

What is the Flexi-Dress?

Vretena worked on the specifications of two scenarios focused on ready-to-wear, urban-fashionable garments that can be applied from “Work to Street”, using two different approaches:

- Material-First Approach, where the garment is designed in response to the material

- Product-First Approach, where the material is developed for an existing garment design

For the Flexi-Dress Vretena took a Material-First Approach. The focuses on the emotional connection to the HighPerCell® material, where the golden hue comes from the unbleached wheat straw fibres, to achieve a local and circular product.

Vretena envisioned the Flexi-Dress as a versatile knitted garment that allows the user to transform it effortlessly from a dress to a stylish top and a straight skirt. In addition, with its reversible V-neck feature, looks can be quickly switched.

The multifunctional way of wearing this garment is linked to the design for circular lifecycle extension: a modular dress with a combination of different knits, natural golden colour, and silky touch.

The Flexi-Dress is designed with the following features for Circular, Bio-based and Local textile ecosystems:

- Bio-based raw materials (man-made cellulosic fibres made from wheat straw)

- Mono-material to support recycling

- No hardware and zero waste pattern

- Made in Europe using networked manufacturing or microfactory concept (ideally)

- Digital prototyping and sampling for reduced waste

- Zero-waste fabric through whole garment knitting (ideally)

- Emotional durability due to fibre story

- Designed for flexibility in the wardrobe and for resale

- Renting and resale business models adopted by Vretena through their online and high street store

- Repair service offered by Vretena

- Product Passport enabled by Circularity ID service

How did we design and produce the Flexi-Dress?

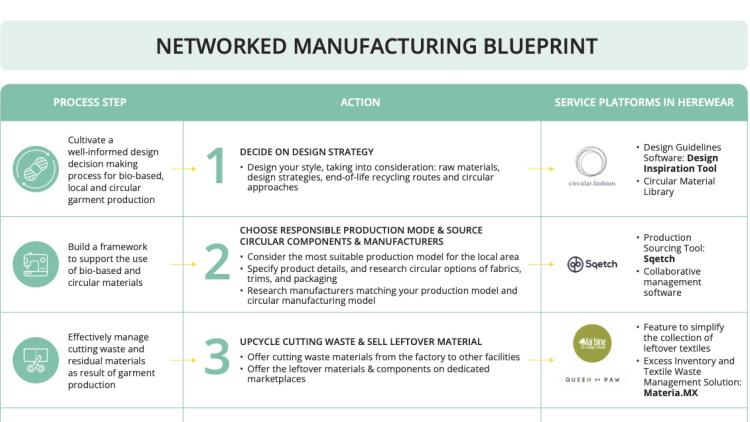

There were six main steps to the garment development process:

- Creative Exploration - using design guidelines and tools

- Early Prototyping - to explore materials and production steps

- Materials Sampling – to explore the possibilities of the materials for the design

- Circularity Checks and Local Modelling – to ensure the design meets the HEREWEAR criteria

- Digital Design – to test the prototypes and prepare for production

- Creation of Tech Packs

The main challenge was to create an opaque textile from multifilaments and to improve the durability and stability of the HighPerCell® fibres which are fine and straight leaving gaps when knitted.

Many knitting trials also aimed to develop a knit design that allowed the top and the skirt to be joined and separate without any additional material types or hardware. A combination was eventually found which achieved these characteristics through knitted slots and belt with a denser knit pattern for modesty.

More detail on how this was achieved can be found in the Bio-based Textiles and Man-Made Cellulosic Fibres sections of the HUB.