Bio-based Dyes

To ensure a textile is fully bio-based, the dyeing stage needs to be considered as well as the manufacture of the textile. In HEREWEAR we tested bio-based dyes on both man-made cellulosic and biopolyester textiles.

The synthetic colorants that are commonly used to dye textiles contribute to a major part of the pollution caused by the textile industry, with nearly 20% of global water pollution being linked to the textile dyeing processes. The use of non-biodegradable, petroleum-based colorants and the release of large proportions of these into the surrounding ecosystem are main contributors to this problem.

In this section you can find out about bio-based textile dyeing, how it is different to conventional approaches, and who can help.

What is bio-based dyeing?

Bio-based colorants used in textiles dyeing are derived from natural resources, such as plants, insects or microorganisms. They had been used in ancient times but were replaced by synthetic colorants which exhibit improved performance, such as range of colours, colour fastness to washing and light. However, as clothing and textile stakeholders are becoming increasingly aware of the catastrophic consequences of synthetic textiles dyeing, there is an increasing interest in developing bio-based dyeing processes.

Why do we need bio-based textiles dyeing?

The synthetic dyes commonly used in the textile industry are non-biodegradable and, when released in the environment, they cause coloration of water, hindering visible light and impairing photosynthesis in aquatic flora. On the contrary, bio-based colorants are mostly biodegradable and their effluents are non-toxic. Furthermore, natural dyes are non-allergenic and do not cause skin irritations.

HEREWEAR proposes alternative bio-based dyeing processes for bio-based textiles so that the final textile is 100% bio-based.

How does bio-based dyeing work?

Bio-based textiles dyeing can be implemented with the same equipment used for synthetic dyes. The dyeing process involves preparation of the bath (dye concentration is adjusted depending on the targeted color depth) and immersion of the fabric in it. Though not necessary, higher temperature may enhance dye absorption into the fabric. In addition, stirring or agitation is required for a more consistent distribution of the dye in the bath. After the fabric is removed from the bath it is rinsed, dried and subjected to thermal fixation (heating and rolling).

Bio-based dye highlights!

- The bio-based colorants tested in HEREWEAR are compatible with current industry equipment and techniques.

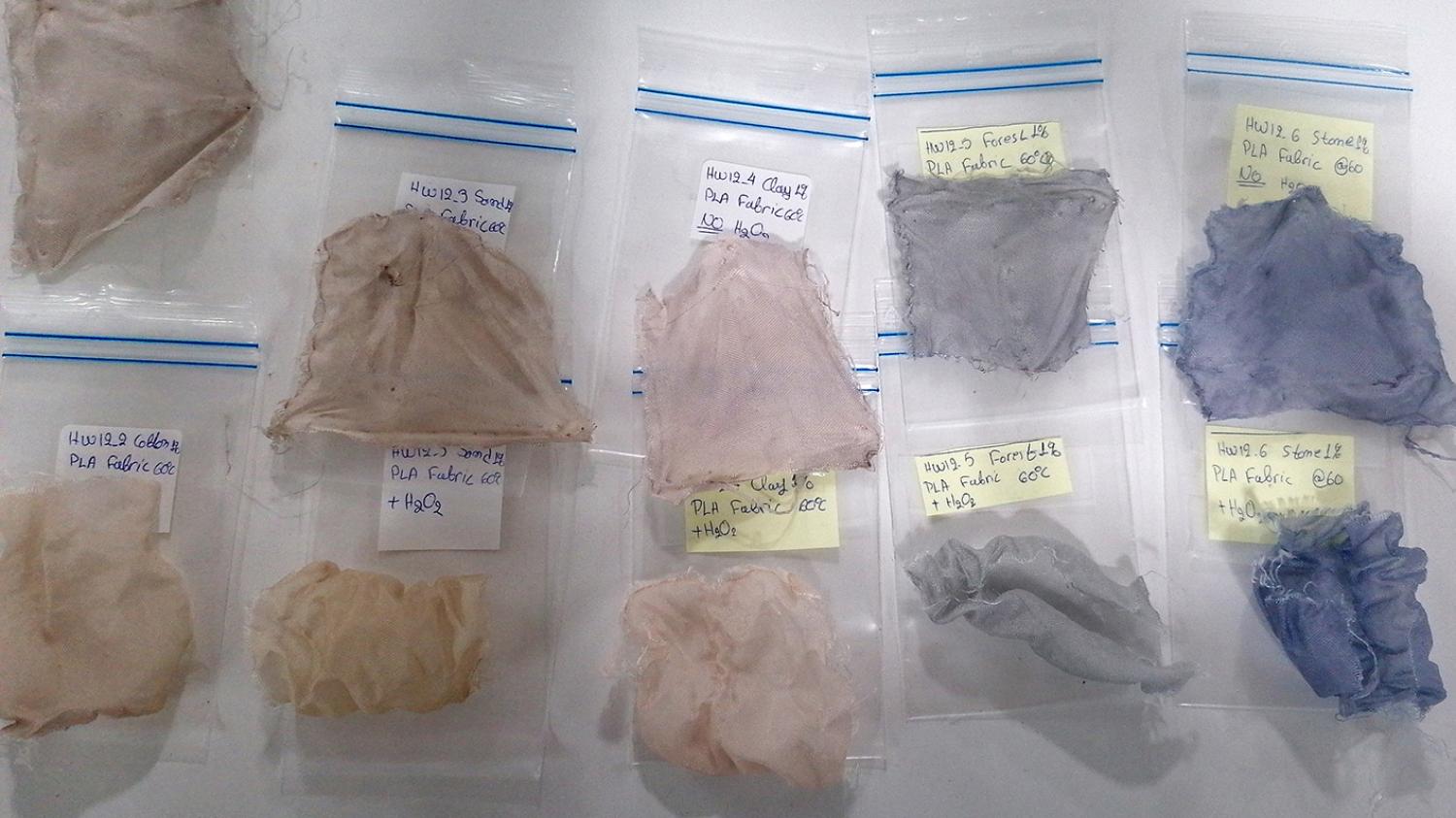

- Cellulosic fabrics can be dyed with commercial bio-based colorants following a vat dyeing approach, reaching satisfactory color fastness. The proposed dyeing temperature is 60oC.

- Finding bio-based dyes appropriate for biopolyester textiles is challenging, as they either do not absorb well or wash out easily. Alizarin and chlorophyllin are acceptable bio-based dye candidates, offering relatively light colors with acceptable fastness. For biopolyester textiles pad-dyeing is preferred over exhaust dyeing to avoid significant fiber strength loss.

- Dyeing blended cellulosic/biopolyester textiles in a two-step process is feasible under appropriate conditions.